| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : DINGSCO

Model Number : According to customers' requirements

Certification : ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : T/T

Supply Ability : Negotiable

Delivery Time : (Sample order) 7 days

Packaging Details : According to customers' requests

Product Name : Inconel 625 Welded Pipe

Heat Treatment : Annealed / Solution / Aging / Hardening

Feature : Seamless Pipe / Welded Pipe

Edge : Mill Edge, Slit Edge

Aplications : Gas Turbine Engines & Heat Exchangers

Package : Woven Packing

Annealing Inconel 625 Welded Pipe Gas Turbine Components High-temperature Applying

1. As a leading Chinese Inconel alloy supplier, DINGSCOmanufactures and produces different sizes of Inconel Alloy 625 pipes.

2. INCONEL® nickel-chromium alloy 625 (UNS N06625 / W.Nr. 2.4856) is used for its high strength, excellent fabricability (including joining), and outstanding corrosion resistance. Service temperatures range from cryogenic to 1800°F (982°C).

3. Inconel 625 welded pipe & tube is a kind of Inconel 625 pipe or tube formed by bending and welding the Inconel 625 strip or Inconel 625 plate, so the quality of raw materials is very important and decisive. In DINGSCO, we choose the raw materials from big factory and use the most advanced splitting and welding technology to manufacture every Inconel 625 welded pipe & tube. If you need solution annealed Inconel 625 welded pipe or tube to meet the higher demand, we can also anneal the pipe or tube with our online solid solution equipment.

4. Customized Dimensions

5. Standards for Inconel 625 Welded Pipe & Tube

6. Chemical Compositions

| S | C | P | Ti | Nb+Ta | Fe | Cr |

| 0.015max | 0.1max | 0.01max | 0.4max | 3.15-4.15 | 5max | 20-23 |

| SI | Mn | Al | Co | Nb+Ta | Mo | Ni |

| 0.5max | 0.5max | 0.4max | 1max | 3.15-4.15 | 8-10 | 58min |

7. Physical Properties

| Density | g/cm3 | 8.44 |

| lb/in3 | 0.305 | |

| Melting Range | ℉ | 2350-2460 |

| ℃ | 1290-1350 |

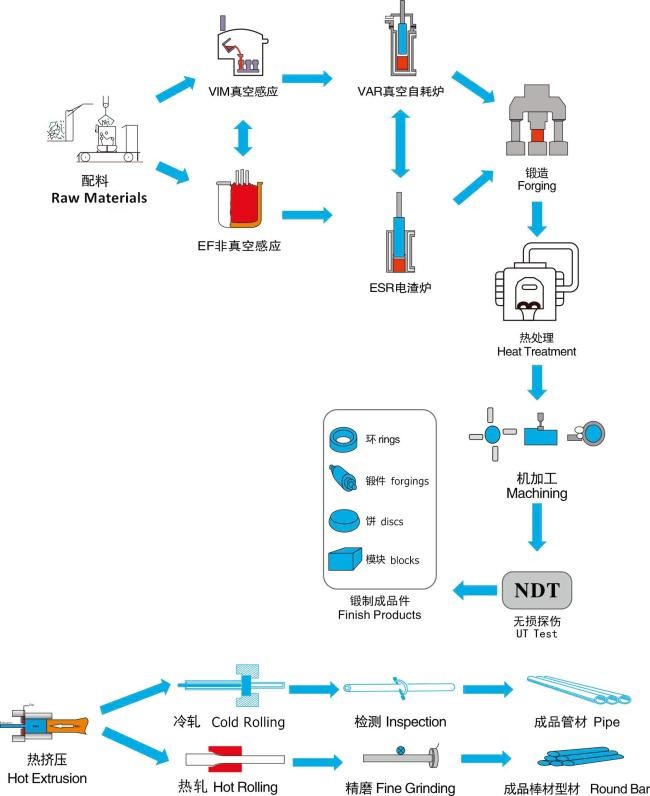

8. Progress Processing

|

|

Annealing Inconel 625 Welded Pipe Gas Turbine Components High-temperature Applying Images |