| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : DINGSCO

Model Number : According to customers' requirements

Certification : ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : T/T

Supply Ability : Negotiable

Delivery Time : (Sample order) 7 days

Packaging Details : According to customers' requests

Product Name : UNS N07718 Inconel 718 Nickel-chromium Based High Temperature Alloy Rod

Material : Nickel based Alloys

Grade : Alloy 718

Size : Customized

Surface : As per your demands

Application Areas : Aerospace, energy, and chemical industry

UNS N07718 Inconel 718 Nickel-chromium Based High Temperature Alloy Rod

Inconel 718 nickel-chromium-based high-temperature alloy rods have become an important material in the fields of aerospace, energy, and chemical industry due to their excellent high-temperature strength, corrosion resistance, and creep resistance.

Material:

Inconel 718 (UNS N07718) is a precipitation-strengthened nickel-chromium-based high-temperature alloy. By adding elements such as niobium (Nb), molybdenum (Mo), aluminum (Al) and titanium (Ti), γ'' (Ni₃Nb) and γ' (Ni₃(Al,Ti)) strengthening phases are formed, so that it can maintain excellent mechanical strength, creep resistance and corrosion resistance at high temperatures.

Main components (wt.%):

Nickel (Ni): 50-55% (matrix)

Chromium (Cr): 17-21% (anti-oxidation/corrosion)

Iron (Fe): Balance (reduces cost and stabilizes austenite structure)

Niobium + Molybdenum (Nb+Mo): ~5% (main strengthening element)

Aluminum + Titanium (Al+Ti): 0.8-1.2% (auxiliary strengthening)

Core characteristics:

| Core performance advantages | |

| Features | Description |

| High temperature strength | High yield strength (≥800 MPa) at 650°C (1200°F) and short-term resistance to 980°C (1800°F). |

| Oxidation resistance/corrosion resistance | Resistant to chloride stress corrosion, sulfide environment, acid and seawater corrosion, more than 5 times better than 304 stainless steel. |

| Fatigue and creep resistance | Not prone to deformation or cracking under high-frequency cyclic loads and long-term high-temperature stress. |

| Weldability and formability | Weldable (TIG/electron beam welding), recoverable by age hardening after cold working. |

Heat treatment:

Solution treatment: 955°C ±10°C, 1 hour/25mm thickness, water quenching.

Age hardening: 720°C ±5°C (8 hours) → 620°C ±5°C (8 hours), air cooling.

| Selection comparison (Inconel 718 vs. other high temperature alloys) | |||

| Alloy | Maximum operating temperature | Key Benefits | Limitation |

| Inconel718 | 700℃ | Best comprehensive performance, high cost performance | When the temperature is >650℃ for a long time, the γ" phase will coarsen. |

| Inconel 625 | 870℃ | Higher corrosion resistance, no age hardening | Lower strength (yield strength ~550 MPa). |

| Haynes 282 | 800℃ | Better creep resistance | High cost and difficult processing. |

Typical application areas

Aerospace: jet engine turbine discs, compressor shafts, combustion chamber components (accounting for more than 50% of aviation alloy usage)

Energy industry: gas turbine blades, nuclear reactor pressure vessel bolts

Petrochemical: downhole tools, valve stems, high-corrosion environment pump shafts

Automobile racing: turbocharger housings, exhaust system high-temperature bolts

Quality Assurance:

Full process control: vacuum induction melting (VIM) + electroslag remelting (ESR) to ensure low oxygen/sulfur content.

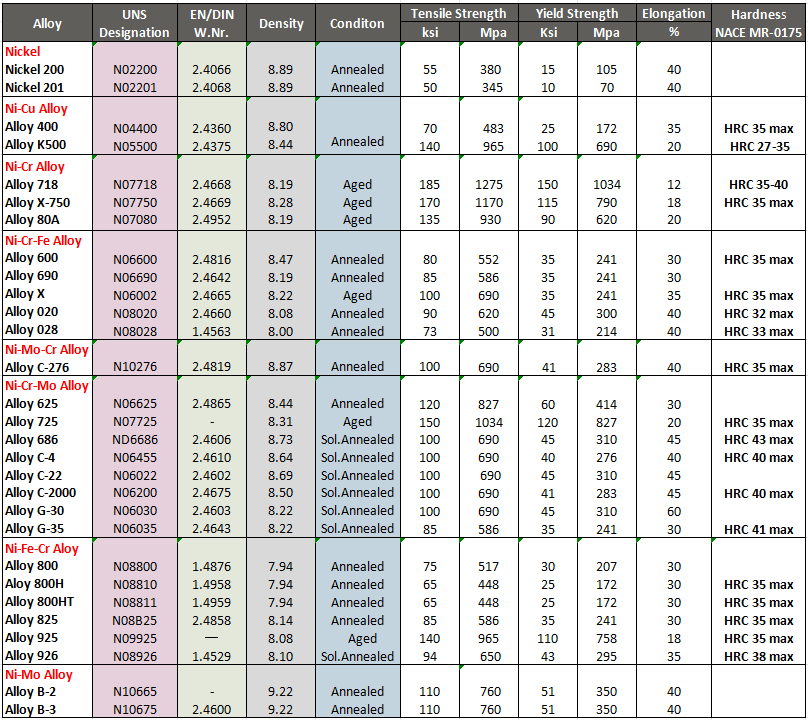

More grades:

|

|

UNS N07718 Inconel 718 Nickel-chromium Based Alloy Rod High Temperature for Chemical Industry Images |